PREMIER MACHINE GRINDING

REBUILDING

COMPETITIVE PRICING

INDUSTRY EXPERTISE

NATIONWIDE

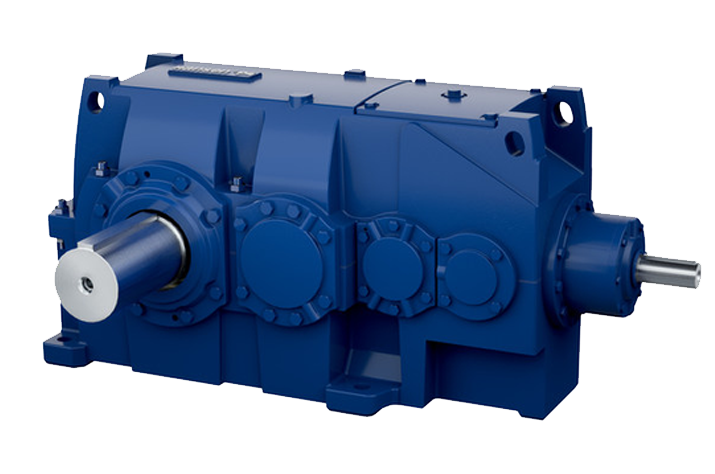

GEARBOX REPAIR

We specialize in the repair and manufacturing of gearboxes & components. We also offer expedited services, pick up and delivery, and unrivaled customer service. We pride ourselves in our commitment to the Customers that we serve. Our customers are why we started in this industry and why we still continue strong today.

TMS is a choice provider of gearbox repair and maintenance services throughout the United States. With our corporate offices based in Houston, Texas our mechanical service team can provide all your pump repairs, servicing, and longevity requirements. Our engineers ensure proper machining, reconditioning, coating, and modifications that will extend the life of your gearbox and rotating elements while keeping you on schedule with your repairs. Our facilities and mechanical service team are equipped to handle any sized gearbox for your industrial and commercial needs, TMS is your source for comprehensive gearbox repair services.

We have established our integrity and loyalty with many prominent companies by repairing and maintaining all their gearboxes. Our field technicians have are trained and certified to work on your units, whether it is a minor repair or a catastrophic failure, we’ll be there for you.

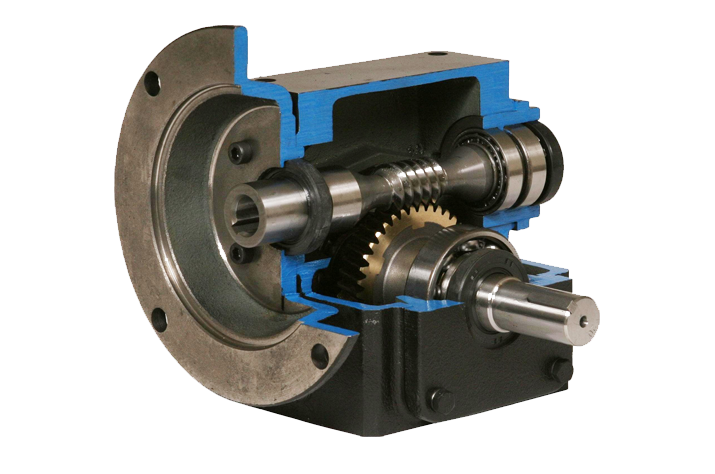

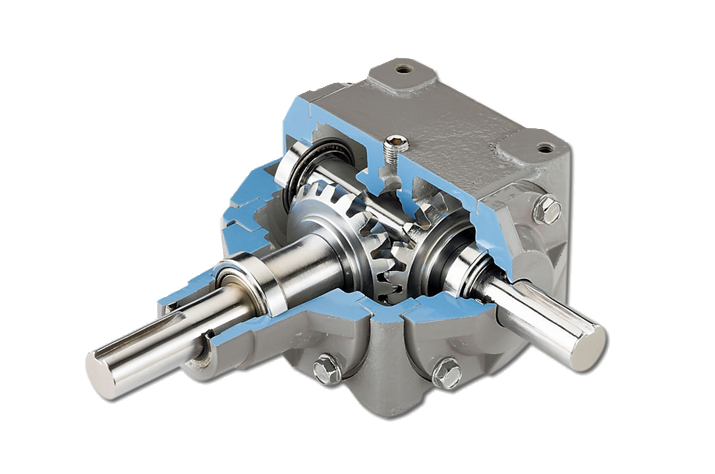

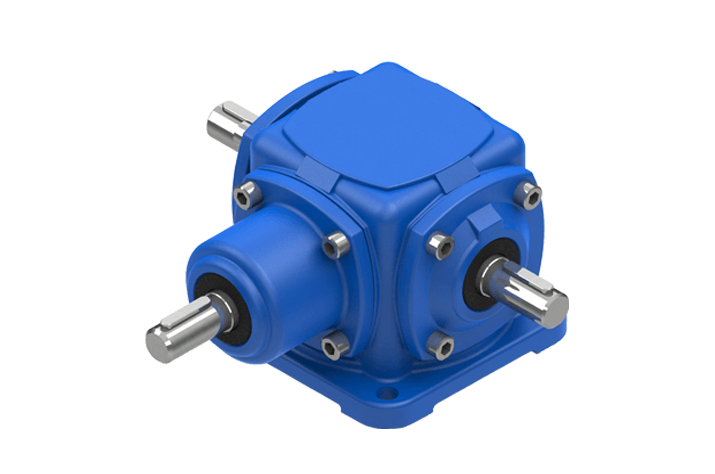

Planitary Gearbox

Worm Gearbox

Helical Gearbox

Bevel Gearbox

Spiral Bevel Gearbox

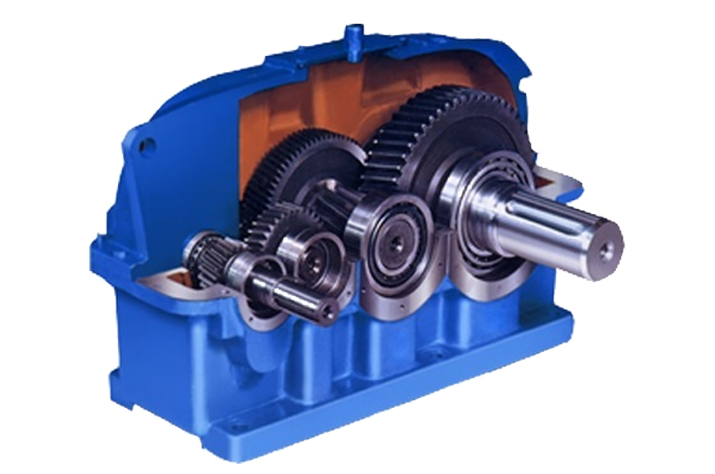

Our Rebuild Process

ANALYZE

We search our inventory to see which equipment best fits your needs. Once determined, we decide what adjustments need to be made.

BREAKDOWN

Our team disassembles and examines the machine to ensure the integrity of every component, then determines what needs to be refurbished or replaced.

FABRICATE

Once the equipment is torn down to its frame, our dedicated, in-house fabrication team gets to work making and repairing components.

REASSEMBLE

We save you future costs by equipping your machine with standardized parts, as well as custom controls provided by our team of certified electricians.

TEST RUN

After reassembly, your machine passes a thorough inspection and is the test run with your product. Each machine comes with a limited warranty and manual for your convenience.

Type of Products We Service

Our repair services include:

- GEARBOX (GEARBOX) REPAIR

- TURBINE REPAIR

- CENTRIFUGE REBUILDING

- CENTRIFUGAL PUMP REPAIR

- ROTATING PUMP REPAIR

- COMPRESSOR REPAIR

- FAN & BLOWER REPAIR

- CENTRIFUGE INSPECTIONS

- CENTRIFUGE MAINTENANCE PROGRAMS

Here’s What You Can Expect from your Gearbox Rebuild:

- RESTORE ALL PARTS TO ORIGINAL MANUFACTURER (OEM) SPECIFICATIONS

- REPLACE ALL BEARING, SEALS, BOLTS AND ANY UNUSABLE OR WORN PARTS

- REBUILD AND HARD-SURFACE CONVEYORS

- REBUILD GEARBOXES AND DRIVE ASSEMBLIES

- DYNAMICALLY BALANCE THE BOWL, CONVEYOR AND GEARBOX ASSEMBLIES

- TEST RUN YOUR GEARBOX AT NORMAL SERVICE SPEED ONSITE

- CLEAN AND REPAIR FRAMES AND CASING ASSEMBLIES

- REPAIR OR MODIFY ELECTRICAL CONTROLS, AS NECESSARY

- BACK UP OUR PROMISE WITH A SOLID WARRANTY ON MATERIALS AND WORKMANSHIP

Capabilities

Machining

- High production/high volume robotic manufacturing cells

- Versatile general machining and repair service to 84″ swing

- CNC machining to 50″ swing x 160″ centers

- 7 axis CNC machining center with 14 foot travel

- Horizontal boring mill capabilities with digital read-out

- CNC & manual milling equipment

- CNC & manual turning equipment

- Prototype manufacturing

Gear Works

- Production & high volume gearing

- Custom Gear Works

- CNC Gear equipment

- CNC Gear Profile Grinding (AGMA Q15 / DIN 1)

- CNC Threaded Wheel Production Gear Grinding

- Gear types: Spur, Helical, Herringbone, Worm gears, Bevel, Spiral Bevel

- Spline types: Internal & External Involute Splines (ANSI & DIN), straight splines

- Sprockets: Single & Multiple strand

- Gear sizes: 1/2” to 120” (10 ft.) [12mm – 3000mm]

- Repair and rerating of gear boxes and drives

- Emergency breakdown service

- Custom made gearboxes, reducers, planetary

Mechanical & Engineering Department Services

- Equipped to provide overhaul on a variety of equipment and machinery

- Product installation services on mobile & stationary equipment

- Repair of rotating equipment

- Multiple Overhead cranes up to 10 ton capacity

- Competent skilled staff dedicated to customer service

- Engineering and Design Department

- Supported with 3-Dimensional Mechanical Design

- CAD & 3D Solids Modelling

- CAE (Computer Aided Engineering)

- CAM (Computer Aided Manufacturing)

- Gear Design Software

- Finite Element Analysis (FEA)

- Research and development

- Field service consulting

- Professional Engineering (APEGA Certified)

Fabrication

- Welding and Fabrication c/w Stress Relieving Facility

- Supported with mig, tig, stick equipment and ironworker machinery

- Capabilities include alloy steel, stainless steel, aluminum and cast iron

- Versatile material cutting capabilities. Band saws – automated & manual

- Oxy-fuel & plasma cutting

Plant Infrastructure

- 70-ton lifting capacity

- Certified welders and non-destructive testing

- EPA approved painting and cleaning facilities with wastewater recovery system

- Plant flows maximized to increase production efficiency and throughput

- Ergonomically designed work cells

- Bearing induction heaters to 10”

- Gear cable induction heating system to any size

- All sites independently ISO certified

Gearbox and Component Test Capabilities

- Magnetic Particle Inspections (MPI) after case hardening and grinding

- Laser alignment on all test stands

- Faro arms for housing and component inspections

- Various test stands capable of achieving full load simulations to 60,000 HP

- Compliant with API testing standards as required

- 2500 HP cooling towers

General Machining Capabilities

- Horizontal boring mill tables up to 98” L x 48” W

- Vertical turning lathes to 42” D

- 300-ton press

- Key seating to 1.5” W x 15” L

- Shaft turning to 40” D x 16’ L

- I.D. grinding to 22” D

- O.D. grinding to 40” D x 100” L

- Turning shafts to 56” D x 120” L

- Jig mill capabilities for housings and components

- Surface grinding to 42” D

- 8’ arm drill press

Gear Manufacturing Capabilities

- Form grinding up to 4 meters

- Gear checking to 4 meters

- Horizontal and vertical 5-axis machining centers

- AGMA quality ratings of 8-15, depending on the application

- CNC gear hobbing to 1.8 meters

- Gear shaving to 90”

- Multiple roll stands to check gear contacts up to 100” center distances and to simulate housing parallelism

- Gear balancing to 30,000 lbs.

- Gear shaping to 36”

- Isolated assembly areas

Millright

Diverse Millwright Services

Our millwright services cover a broad range of emergency repairs and routine maintenance to keep your company moving forward. Our millwright team is dedicated to not only repairing your existing equipment but managing the balance of the plant and major overhaul projects.

Emergency Equipment Repairs

For facility owners, maximizing uptime while ensuring the safe and efficient running of the facility contributes directly to the bottom line. Our self-perform breakdown services are integral to emergency maintenance operations across the heavy industry and by hiring a contractor such as us with the right expertise and equipment, there are numerous tangible advantages.

Routine and Preventative Maintenance

Our highly skilled team can maintain, repair, and install your plant machinery and equipment offering cost-effective solutions for various operating systems. Whether it’s affecting plant productivity or exposure to a dangerous work environment, we have the necessary tools and equipment to accommodate major routine and preventative maintenance outage work with speed and efficiency.

Examples of Equipment We Service

Any rotating and fixed machinery in your industrial facility are covered by our millwright services. From bulk handling gearboxes to turbines and pumps, our team can handle your equipment. With vast experience and in-depth knowledge of rotating equipment installations, modifications, and repairs, our millwrights deliver outstanding results under the toughest deadlines and tightest tolerances. Our equipment serviced includes:

- Turbines

- Centrifuges

- Centrifugal Compressors

- Pumps

- Gear Boxes

Working with TMS as your maintenance partner means we can help to plan all major construction activities on your site from the earliest stages of an operation. Our ability to supply alternative equipment and propose different approaches results in reduced timelines, improved safety, and lower costs.

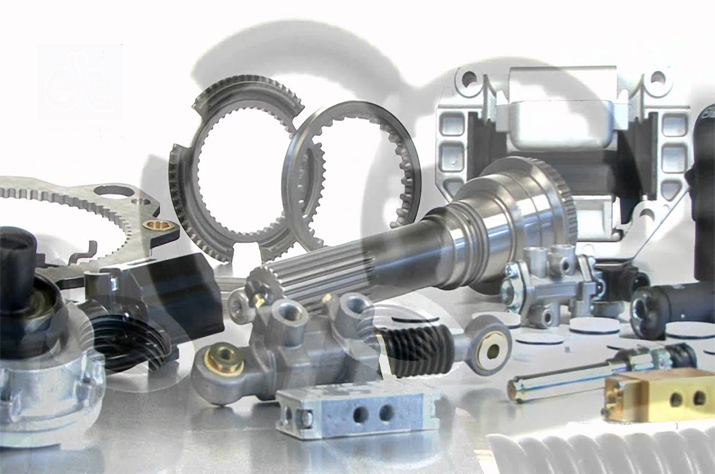

Replacement Parts

TMS supplies a full range of replacement spare parts for gearboxes. Our spare parts comply with the latest specifications and prolong the lifecycle for your installation. On-going research and development ensures that you will always get the latest applicable parts and ensured reliability. Our supplied parts give you a true cost-efficient peace of mind.

We provide a full-service solution for gearboxes consisting of repair, balancing, upgrades, and refurbishment. We offer a complete line of high-quality replacement parts for many manufactures of gearboxes. This includes all of the major rotating assembly components, as well as pumps, control panel-related components. We also provide both major and intermediate bearing and seal kits.

-

Large inventory of parts

-

In-stock OEM and TMS manufactured parts for common brand gearboxes