PREMIER MACHINE GRINDING

REBUILDING

COMPETITIVE PRICING

INDUSTRY EXPERTISE

NATIONWIDE

Centrifuge, Separator Repair & Engineering

We service multiple brands, “One Stop” Service – Alfa Laval, Tetra Pak, and Westfalia

We understand that any shutdown due to a centrifuge malfunction or parts shortage represents an emergency situation. With most of our customers running two or even three shifts, seven days a week, their centrifuges must operate at peak efficiency levels at all times. We understand that any downtime equates to unhappy customers, missed deadlines, scheduling disasters, logistical nightmares, and confused employees … all of which impact reputation and profits.

We proudly provide rapid, on-site World-Class repair service by our reliable engineering and technical support staff. When you call us with a problem, we treat it as an emergency that receives the very highest priority: we expedite repair in order to get your equipment back online ASAP, and then we offer a variety of maintenance programs to keep your equipment operating at peak efficiency 24/7/365.

Turbo Machining Solutions offers complete centrifuge repair, rebuilding, and reconditioning for the oil, industrial, agricultural, and wastewater management industries. Not only can we repair with all working parts, our engineers employ new technology which enables us to restore your centrifuge to OEM specifications (or better) or tailor the equipment to meet your specific requirements. When we rebuild or repair your centrifuge, you can expect it to perform as good as (if not better) than the day it was delivered new. Our goal is to extend the life of your assets and minimize any potential downtime.

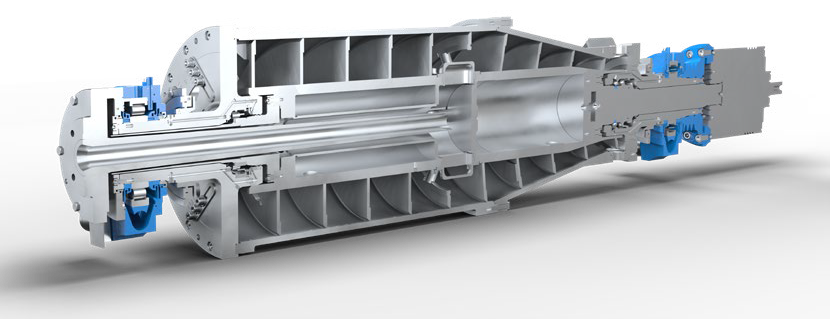

DECANTER CENTRIFUGE

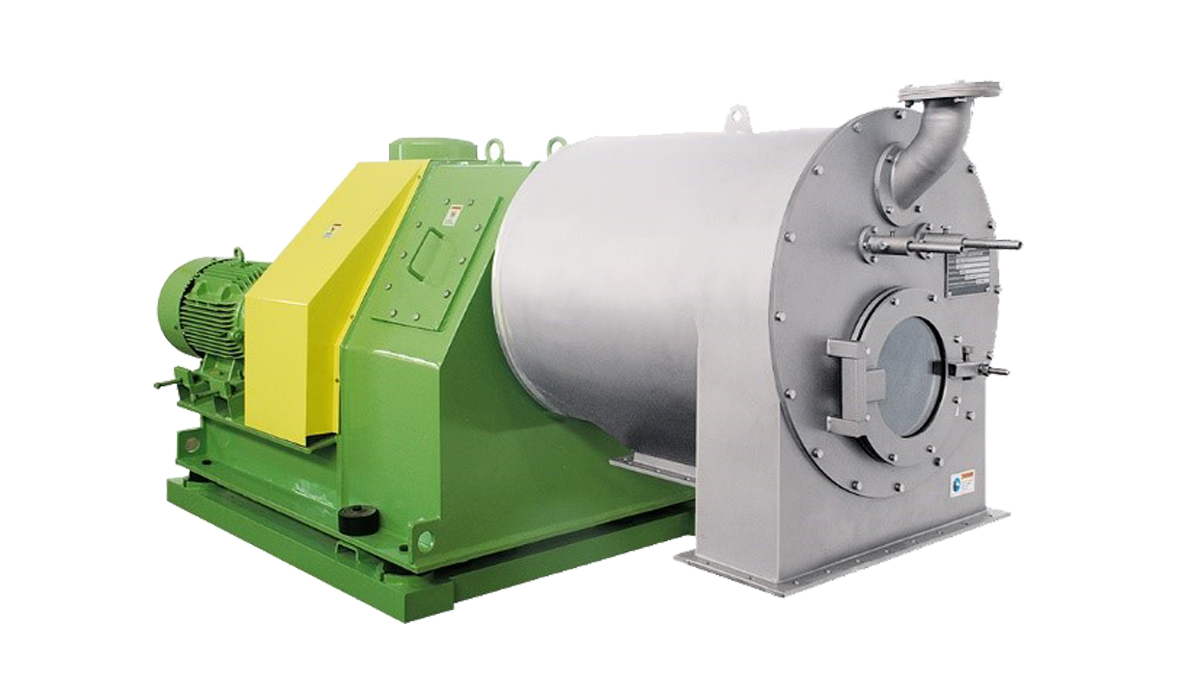

BASKET CENTRIFUGE

PUSHER & PEELER CENTRIFUGE

DISC STACK CENTRIFUGE

WESTFALIA CENTRIFUGE

Type of Products We Service

Our centrifuge repair services include:

- CENTRIFUGE REBUILDING

- CENTRIFUGAL PUMP REPAIR

- ROTATING PUMP REPAIR

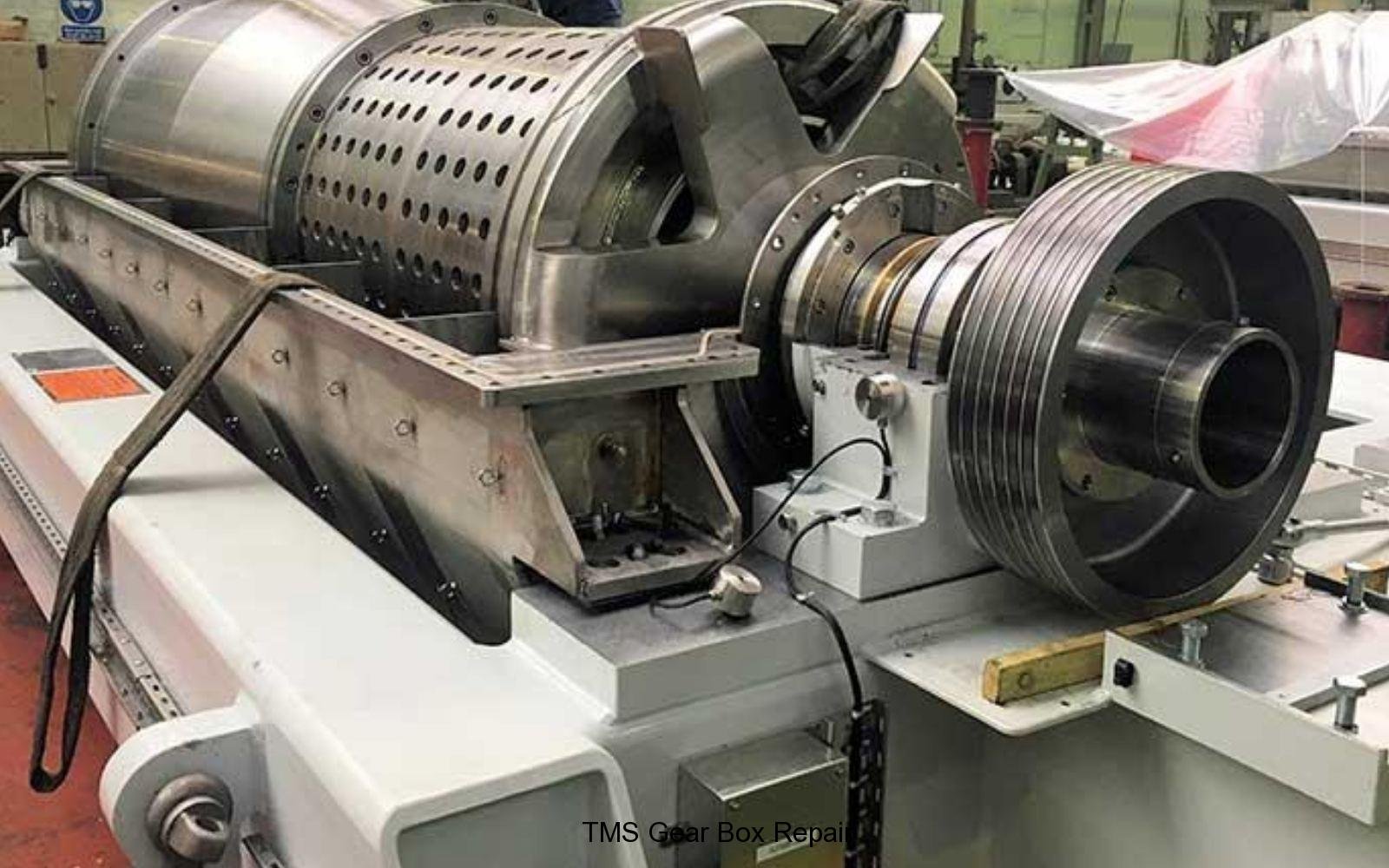

- GEAR BOX (GEARBOX) REPAIR

- TURBINE REPAIR

- COMPRESSOR REPAIR

- FAN & BLOWER REPAIR

- CENTRIFUGE INSPECTIONS

- CENTRIFUGE MAINTENANCE PROGRAMS

Here’s What You Can Expect from your Centrifuge Rebuild:

- RESTORE ALL PARTS TO ORIGINAL MANUFACTURER (OEM) SPECIFICATIONS

- REPLACE ALL BEARING, SEALS, BOLTS AND ANY UNUSABLE OR WORN PARTS

- REBUILD AND HARD-SURFACE CONVEYORS

- REBUILD GEARBOXES AND DRIVE ASSEMBLIES

- DYNAMICALLY BALANCE THE BOWL, CONVEYOR AND GEARBOX ASSEMBLIES

- TEST RUN YOUR CENTRIFUGE AT NORMAL SERVICE SPEED ONSITE

- CLEAN AND REPAIR FRAMES AND CASING ASSEMBLIES

- REPAIR OR MODIFY ELECTRICAL CONTROLS, AS NECESSARY

- BACK UP OUR PROMISE WITH A SOLID WARRANTY ON MATERIALS AND WORKMANSHIP

Our Rebuild Process

ANALYZE

We search our inventory to see which equipment best fits your needs. Once determined, we decide what adjustments need to be made.

BREAKDOWN

Our team disassembles and examines the machine to ensure the integrity of every component, then determines what needs to be refurbished or replaced.

FABRICATE

Once the equipment is torn down to its frame, our dedicated, in-house fabrication team gets to work making and repairing components.

REASSEMBLE

We save you future costs by equipping your machine with standardized parts, as well as custom controls provided by our team of certified electricians.

TEST RUN

After reassembly, your machine passes a thorough inspection and is the test run with your product. Each machine comes with a limited warranty and manual for your convenience.

The difference between a new centrifuge and a remanufactured centrifuge is price. The functionality, the quality, and the warranty of a remanufactured centrifuge is equal to that of an OEM.

The difference between a used centrifuge and a remanufactured centrifuge is more significant.

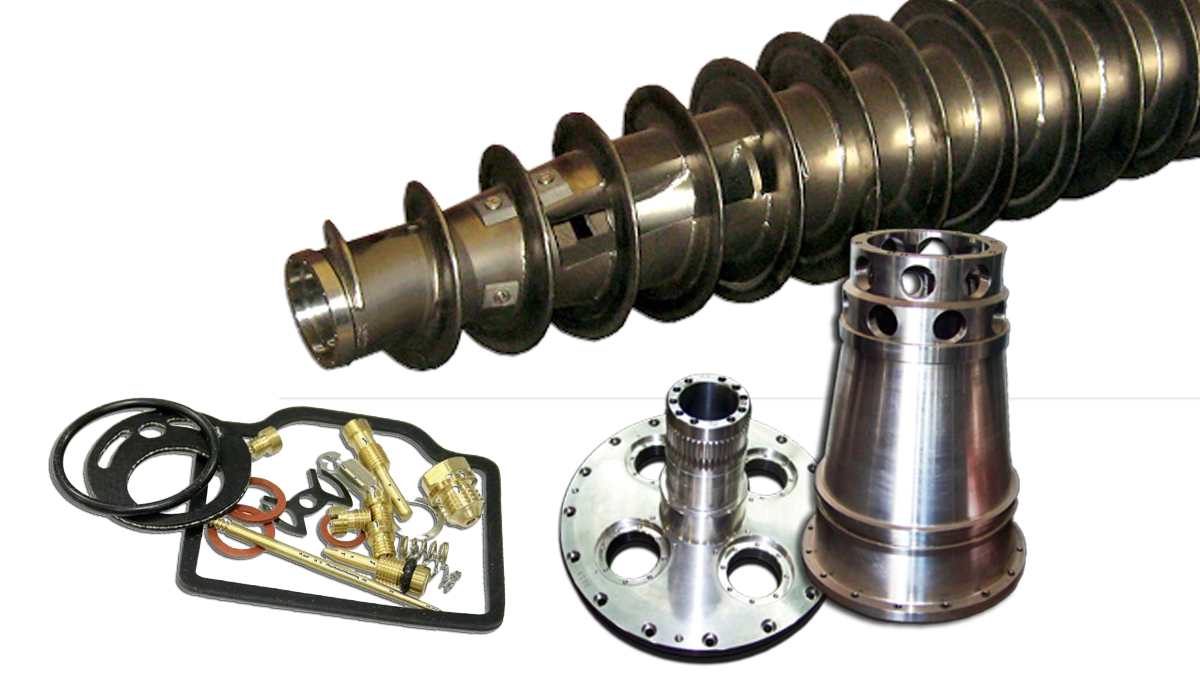

Replacement Parts

TMS supplies a full range of replacement spare parts for centrifuges. Our spare parts comply with the latest specifications and prolong the lifecycle for your installation. On-going research and development ensures that you will always get the latest applicable parts and ensured reliability. Our supplied parts give you a true cost-efficient peace of mind.

We provide a full-service solution for decanter centrifuges consisting of repair, balancing, upgrades, and refurbishment. We offer a complete line of high-quality replacement parts for many manufactures of centrifuges. This includes all of the major rotating assembly components, as well as gearboxes, control panel-related components. We also provide both major and intermediate bearing and seal kits.

-

Large inventory of parts

-

In-stock OEM and TMS manufactured parts for common brand centrifuges